Some recent knitting related ebay purchases have been making me smile to myself recently. First up, this is not a mini beehive made by perfectly colour co-ordinated bees. It is in fact a bakelite wool holder made by Patons to match their old Beehive line of yarn.

It even has a needle gauge in the bottom...

I have a couple of Patons Beehive DK vintage patterns I picked up in a charity shop yonks ago and I now feel compelled to knit them from my wool holder immediatly.

The second item was somewhat larger and a lot heavier... an umbrella swift, featuring a cast iron base.

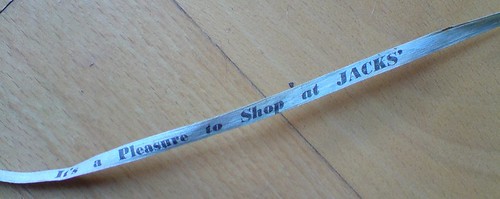

I bought this somewhat on a whim, it has to be said. I was a little embarrassed that I'd bought such a big, heavy contraption, but I will also admit I fell rapidly in love with it. First of all it arrived coated in cobwebs and tied up with this old paper ribbon (which I kept).

Then, when I opened it out for the first time, I was confused. I'd read up on swifts while I was waiting for this one to be delivered and they seemed to involve lifting up from the bottom and securing. This had no such method to hold the expansion of the arms, I was confused. So I started cleaning it up, eradicating the cobwebs and making a couple of minor repairs (it was pretty old). As I attended to the grime it became obvious it was no ordinary swift, or at least not shop bought. It became obvious quickly that it was handmade, and then when I was looking at the base, it clicked.

This was a reduce, reuse, recycle at it's best - resourcefulness the old fashioned way. The swift had been a standard lamp in a former life. The central pole had been sawn off at the base and a brass metal rod inserted through the bottom and secured. The top and bottom cogs that hold the arms in place had been carved from the same central pole, but from a bulbous decorative section that probably held the light fitting. The swift moves easily on it's metal rod, but the heavy nature of the cast iron base and the arm holder at the top meant that it was designed to rely on gravity alone...

When you looped the skein around the arms and let the top of the swift drop, the yarn held the arms in place naturally. No securing necessary. As it twirls around it creaks gently with it's age. As a wound my first skein into a ball an entire romance formed in my mind based on this swift....

A farmer short on time in harvest season, had no time (or patience) to help his wife wind her skeins. This familiar duty, with arms held apart, had become irksome. She, on the other hand, was trying to get a jump on the winter chills approaching - the two feelings were not compatible. One night the farmer stayed out late in the workshop, he'd seen a contraption in a fancy department store in town (It's a Pleasure to shop at JACKS') that would solve this problem. He had in his hands an old standard lamp from the days of gas. They had electric lights now and this lamp had no further use. Measuring, sawing, carving the swift began to take shape. The farmer loved his wife, despite his lack of desire to help with wool winding, so he finished it with care. He added a decorative finial on top, and matching elongations to the uprights of the swift. Sanded the edges. Stained the wood pieces and coated with varnish. He presented the swift to his wife somewhat sheepishly, but she was over joyed.

As she wound the first balls from the swift she planned a jumper in her minds eye. That first jumper went to the farmer to keep him warm through winter, with a few extra details in the neat finishes and seams - made with love. The farmer didn't appreciate these details consciously, but the jumper was exceedingly warm, and kept out the wind in an unparalleled fashion. He wore it every day of winter, every winter, for the rest of his days - with only a little wear that needed darning in the elbows...

No comments:

Post a Comment

Thanks in advance for any comments sent my way, they arere always appreciated!